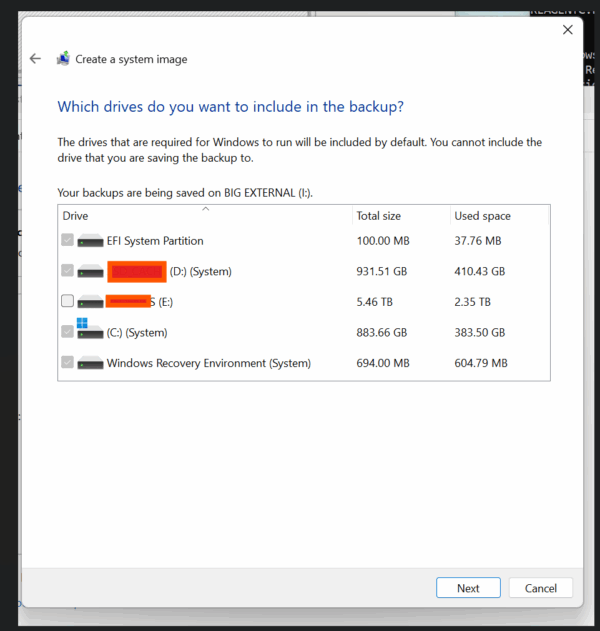

I recently spent far too many hours wrestling with an odd behavior in Windows 11:

when creating a System Image Backup with the built-in Backup and Restore (Windows 7) tool, Windows insisted on including my D: drive as part of the “system image.”

The problem?

-

My OS lives on C: (NVMe).

-

EFI and Recovery partitions are correct.

-

D: is just a data/games disk.

Yet the backup wizard grayed it out as “System” and demanded to include it.

Chasing Ghosts

Like any good sysadmin, I went through the usual suspects:

-

BCD (Boot Configuration Data):

bcdedit /enum all → no references to D:.

-

VSS (Volume Shadow Copy):

vssadmin list shadowstorage → nothing allocated on D:.

-

Mount points and recovery:

mountvol showed C:, EFI, and Recovery only.

WinRE was on the right recovery partition.

Still, the backup wizard stubbornly listed D:.

The Smoking Gun: CBS Registry Entries

After some deeper digging, I hit the jackpot:

the Component Based Servicing (CBS) registry hive contained hundreds of stale entries like:

HKEY_LOCAL_MACHINE\SOFTWARE\Microsoft\Windows\CurrentVersion\Component Based Servicing\Packages\...

InstallLocation REG_SZ \\?\D:\wd\compilerTemp\...

At some point, Windows Update had used D: as a scratch/temp directory.

CBS dutifully recorded those paths as part of the “system.”

So when Backup scanned the servicing database, it decided D: must be critical.

The Fix

The key was forcing CBS to rebuild itself:

DISM /Online /Cleanup-Image /StartComponentCleanup

DISM /Online /Cleanup-Image /RestoreHealth

sfc /scannow

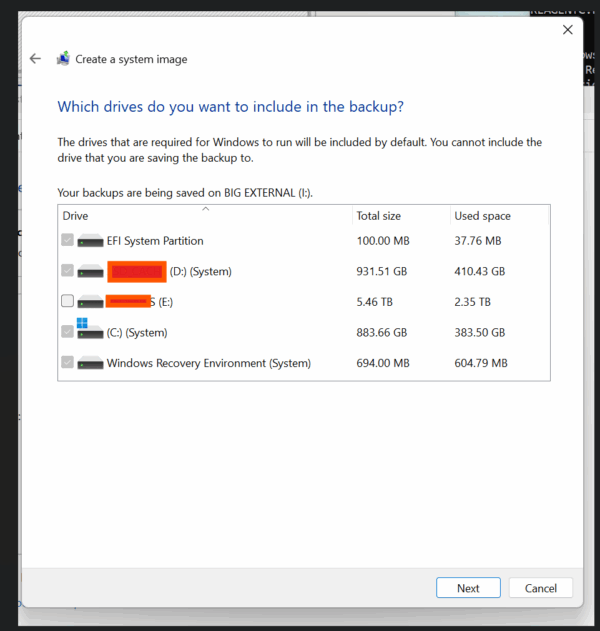

Patience paid off: it eventually finished, cleaned up the junk, and a reboot later…

The backup wizard no longer forced D: as “System.”

Running:

DISM /Online /Cleanup-Image /CheckHealth

Great success!

Lessons Learned

- Windows Backup (Windows 7) is ancient.

It keys off CBS, BCD, and a variety of heuristics. If anything in your system state points to a drive, it might get flagged as “System.”

- It’s not always just boot data.

Services installed on another drive, drivers, scheduled tasks, even leftover registry entries can make a disk appear “critical.”

- The only truth in Windows is the Registry.

On Linux, you’d search /etc/.

On Windows, if you want the real answer to “why does the OS think this drive matters?” →

grep the damn registry.

reg query HKLM /f "D:\" /s

- That’s how I found the culprit.

Should You Bother?

Honestly, Microsoft hasn’t touched this tool in years.

For imaging, you’re usually better off with Veeam Agent which has a free full blown community edition! , https://archive.org/details/Macrium_Reflect_Free_Latest, or some other recent tool. They let you pick exactly which partitions matter.

But if you’re stubborn (like me) or want the satisfaction of making Windows behave:

- clean up CBS,

- check the registry,

- and remember: if a disk shows up as “System,” don’t just trust Disk Management — chase the references until you kill them.

Final Word

This bug wasn’t about bootloaders or UEFI quirks. It was about Windows Update leaving crumbs in CBS.

Once those registry ghosts were gone, Backup behaved.

So, next time you’re fighting Windows Backup…

Search the registry first. Always.

That’s All Folks 😀